Discover the process for plastic injection moulding

Prime Biopolymers develops compostable bioplastic grades suitable for use in conventional machinery, for all types of manufacturing methods. One of them is plastic injection moulding. Today we talk about what injection moulding is, what this process consists of, and its main advantages.

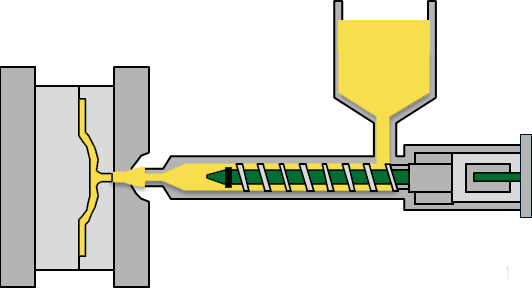

Plastic injection moulding is a manufacturing process using moulds. This process consists of melting plastic materials through heat and injecting them into a mould that has the desired shape. Once the part is formed, it is cooled and ejected.

Injection moulding receives this name because it is a very similar manufacturing process to injecting fluids with a syringe.

The process for plastic injection moulding

This process is carried out in different stages. We can simplify the manufacturing method into 3 parts:

Phase 1: Injection

For starters, a material is placed in a hopper, as is done in extrusion.

It then passes to the screw (or worm) which is at high temperature, allowing the material to melt and become fluid. The fluid is then pushed into the nozzle through which the mould is filled.

In this way, the mould is filled to create the desired part shape.

Phase 2: Cooling

Once the injection has been made, as the mould is at low temperature and closed under pressure to avoid possible leaks, the material solidifies.

Phase 3: Ejection of the piece

When the piece made by plastic injection moulding is in a solid state, the mould is opened and the piece is ejected. This manufacturing method is not a continuous process as thermoforming is, instead, it is necessary to wait for empty moulds to be available in order to continue.

In order to make the different products correctly, it is necessary that the machines involved in the injection moulding process work with great precision, as all parts must be exactly the same.

Plastic materials for injection moulding

Tipocally, thermoplastics, elastomers and thermosetting materials are used in the plastic injection moulding process.

With plastic injection moulding, polymers and granular compounds are usually processed. Milled substances, color concentrates and additives are also used. As far as the technical parameters are concerned, the processing in the different materials presents big differences. For instance, varying temperatures, cooling times, spindle speeds…

Prime Biopolymers has developed bioplastic injection moulding grades that meet all the properties required for successful plastic injection moulding.

Prime Biopolymers catalogue has different injection grades suitable for different types of applications: caps, jars, lids… These grades have been developed to be introduced in conventional machinery so that our customers do not have to make any kind of modification in their machinery. In this way, additional investment in new infrastructures is avoided.

Injection moulding machinery

There are different types of machines in plastic injection moulding:

- Motorized machines driven by servomotors

- Hydraulic machines driven by hydraulic motors

- Hybrid machines driven by a combination of a servomotor and a hydraulic motor

Regarding the structure of a plastic injection moulding process machine, we can say that it consists of an injection unit that injects the material to fill the mould and a clamping unit that acts on the mold.

In recent years, the use of CNC (Computer Numerical Control) has been increasingly used in injection moulding machines, resulting in the popularity of models that allow high-speed injection under programmed control.

How does a plastic injection moulding machine work?

Injection unit

The main task of this part of the machine is to melt the material, mix it and inject it. To carry out this function, different types of screws are used depending on the polymer to be injected.

This injection unit is equipped with heaters that maintain a constant programmed temperature.

Closing unit

It concerns a press that closes under pressure and ensures that during the injection of the material there are no leaks or escapes. It is essential that this does not occur, otherwise the part/piece/item could have numerous defects.

Injection moulds

The mold is the space where the piece is generated. Each part needs a different mold. Thus, when you want to change the product being produced, you simply change the mold.

Injection moulding applications

There are numerous types of parts and objects that can be manufactured through plastic injection molding. It is a manufacturing process through which large quantities can be produced with numerous types of molds for a wide range of industries.

They can be manufactured with thicknesses that cannot be reached with other methods such as thermoforming. Large pieces such as chairs or containers can also be produced.

An example of items that can be produced in large quantities with injection moulding can be caps, lids, automotive parts, trays, glasses, coffee capsules…

Advantages of plastic injection moulding

Plastic injection moulding has numerous advantages:

- Precision: thanks to the mould and the accuracy with which the parts are manufactured, identical parts can be produced continuously. This is why in sectors such as the automotive industry, which require high precision, we often see the use of this manufacturing method.

- Low waste: injection moulding generates little waste and material loss.

- Wide range of moulds: injection moulding makes it possible to manufacture a wide variety of pieces thanks to the possibility of using different moulds in the same injection moulding machine. In addition, complex pieces with a large number of details can be produced.

In conclusion, plastic injection moulding is a widely used technique due to is efficiency and precision. Prime Biopolymers has different grades of ZIMIA bioplastic that are optimal for injection moulding.