Maniplastic validates ZIMIA for thermoforming

Maniplastic, a company dedicated to manipulating and transforming technical plastics, has conducted industrial manufacturing of thermoforming trays made from the compostable bioplastic grades of Prime Biopolymers.

The transformer company, based in the city of Burgos, has over 30 years’ experience in the sector. It offers, accomplishes and manufactures both standard and bespoke solutions.

The project forms part of a complete collaboration between the two companies aimed at meeting the new demands of the industrial sector and thus obtaining a 100%-compostable material for the different markets in the plastics sector.

“The conclusions of the project have been favourable, and they show that mass production is possible”

What was the process?

First of all, Prime Biopolymers, a bioplastics company, has developed a bio-based and compostable material suitable for industrial manufacturing of thermoformed products.

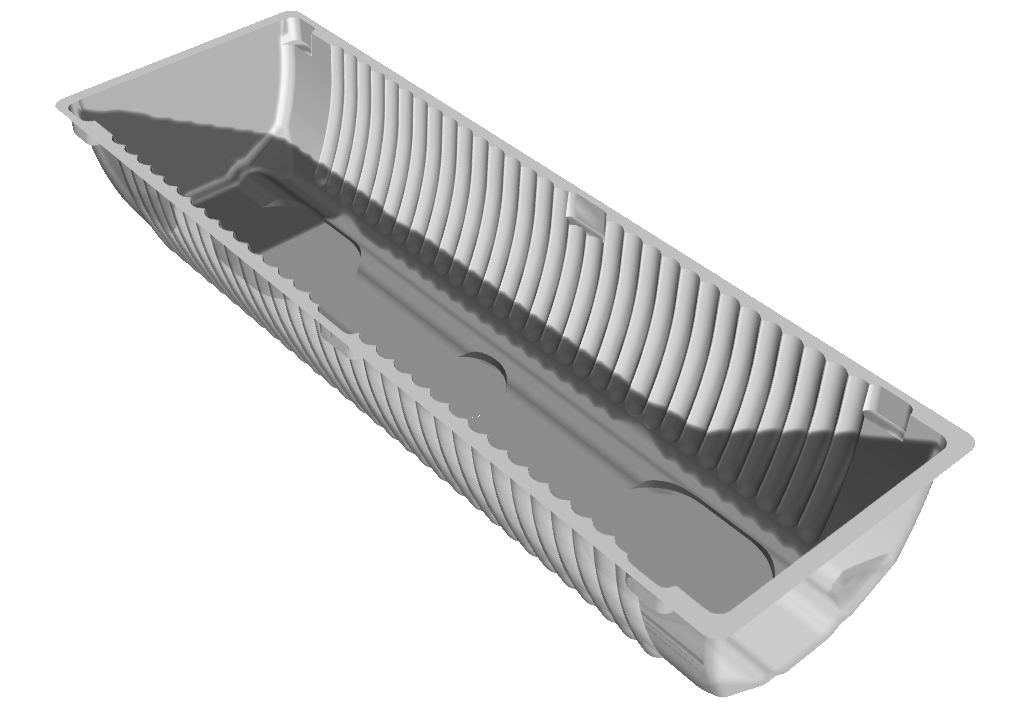

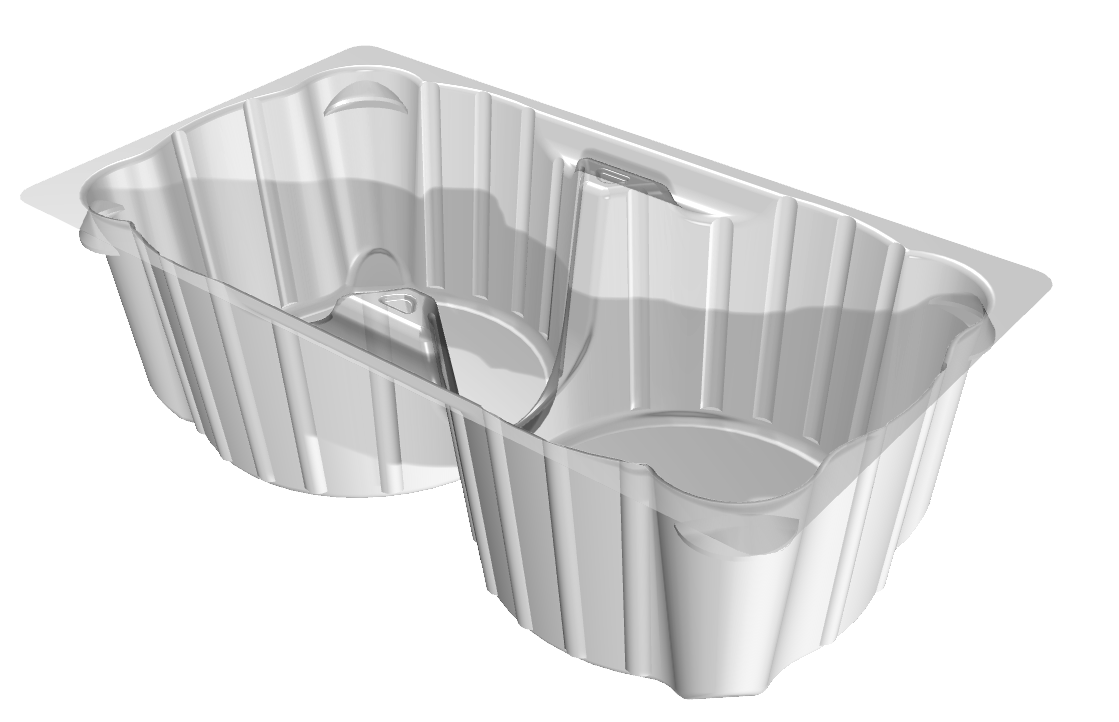

Maniplastic participated in the transformation process by producing trays and blisters from a spool of the material ZIMIA.

After receiving the material and following specifications of Prime Biopolymers, the pieces were moulded, taking into account factors like the pressure, times and speeds required by the ZIMIA grades.

Exceeding expectations

After trying the material, “the expectations and conclusions of the process were favourable, showing that mass production is possible”, says Maniplastic.

In fact, the transformer company confirms that “the material adapts perfectly to the different production processes of vacuum moulding and die-cutting”.

As Maniplastic says, the behaviour of the material ZIMIA “surprised us by how well it settled into the cavities in each of the preform matrices”.

This compostable material can distribute and capture the dissipation temperature, “offering homogeneity for vacuum moulding”, according to Maniplastic.

Among other merits, Maniplastic has a highly focussed vision of the future of its market. This is a company working on a continuous process of innovation and development for its products in a large number of sectors.

Its philosophy rests on three solid pillars: quality, service and innovation.

The alliance between Maniplastic and Prime Biopolymers is the perfect match because both work each day to become an active part of the companies they collaborate with, by bringing ideas to achieve a sustainable future based on the circular economy.